Rotoscreen - X

Rigid Tapes Print

Machines > Narrow Fabric Solution > Rotoscreen X

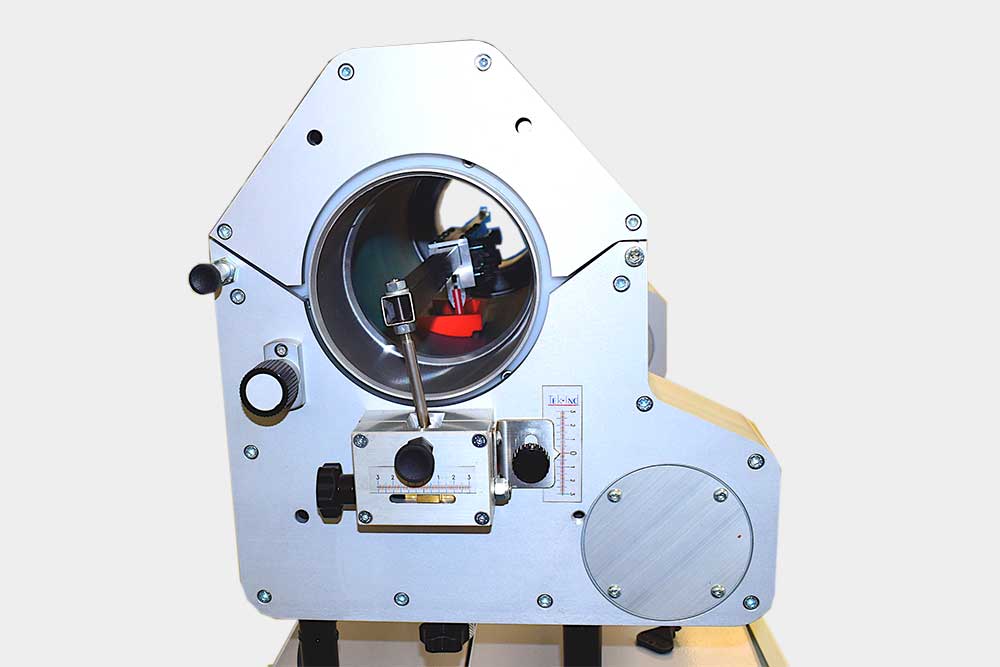

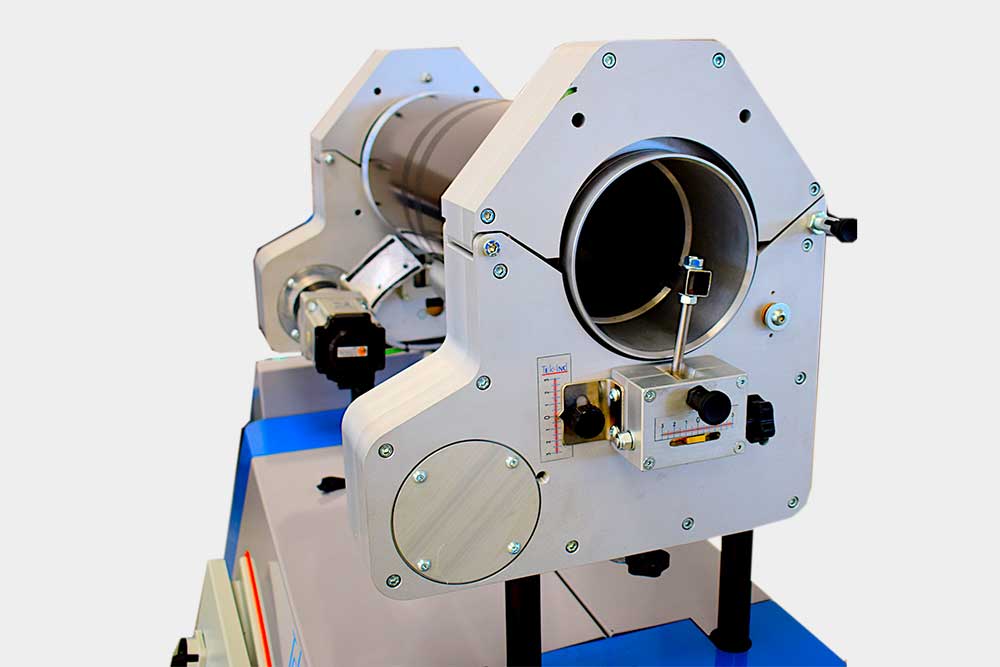

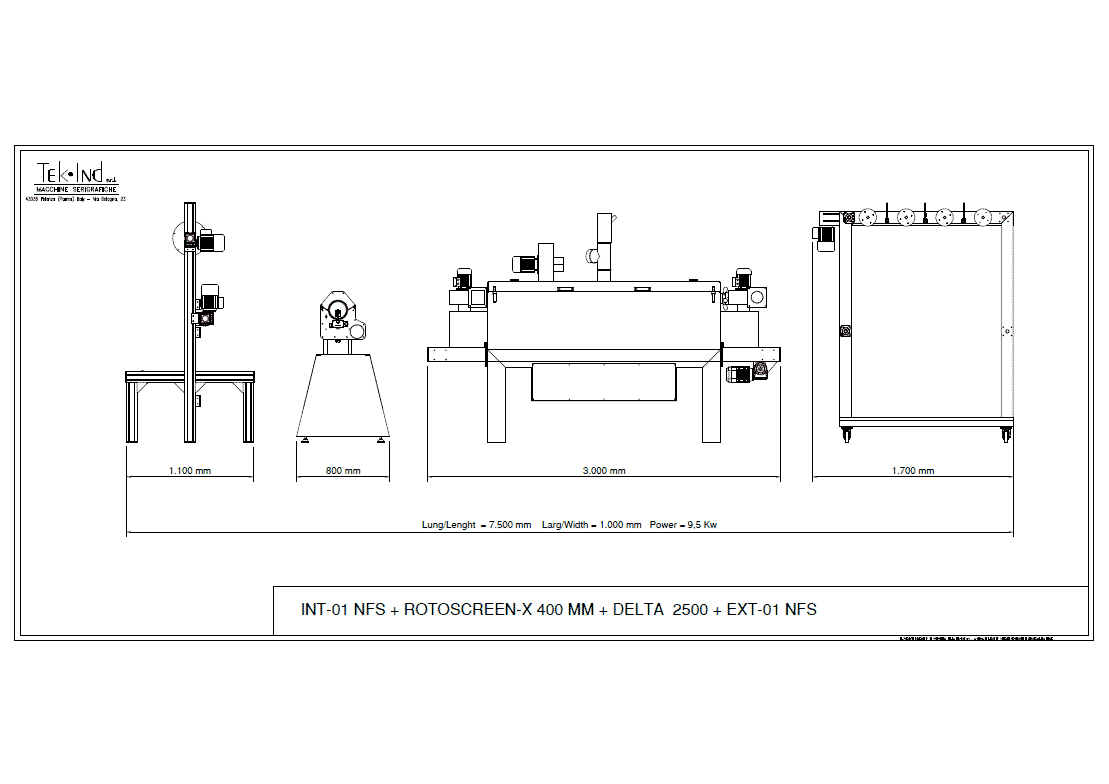

The Rotoscreen machine in the version without carpet but with only cylinder and counter-cycle, allows to print rigid narrow fabric, it can be applied inside an already existing coating line. The belt is driven by the motorized counter cylinder, which adjusts its speed according to the speed of the printing cylinder. It is possible to use water-based inks, plastisols and silicones; the ink loading can be performed manually using an iron spatula or a SP-Pump Series (gear silicone pump). The carpet-free Rotoscreen machine is available in the 400 mm cylinder and 800 mm cylinder versions; it is possible to mount cylinders with a circumference of 640 mm and 820 mm. The Rotoscreen printing machine without carpet, if not added in an existing line, requires an introduction INT; of an oven for drying the ink Delta and one exit to boxes or coil EXT-01.

MAIN TECHNICAL FEATURES

- Printing technology Rotative printing with Cylinder

- Printing Typology Monocolour rotative printing, ideal for continuous graphics

- Printable Narrow Fabric Only Rigid narrow fabric

- Mountable Cylinder 640 mm / 820 mm

- Printing Width 400 mm / 800 mm

- Production capacity 15 MT/min MAX

- Installed power 1 Kw

- Air Consumption No Compress air needed

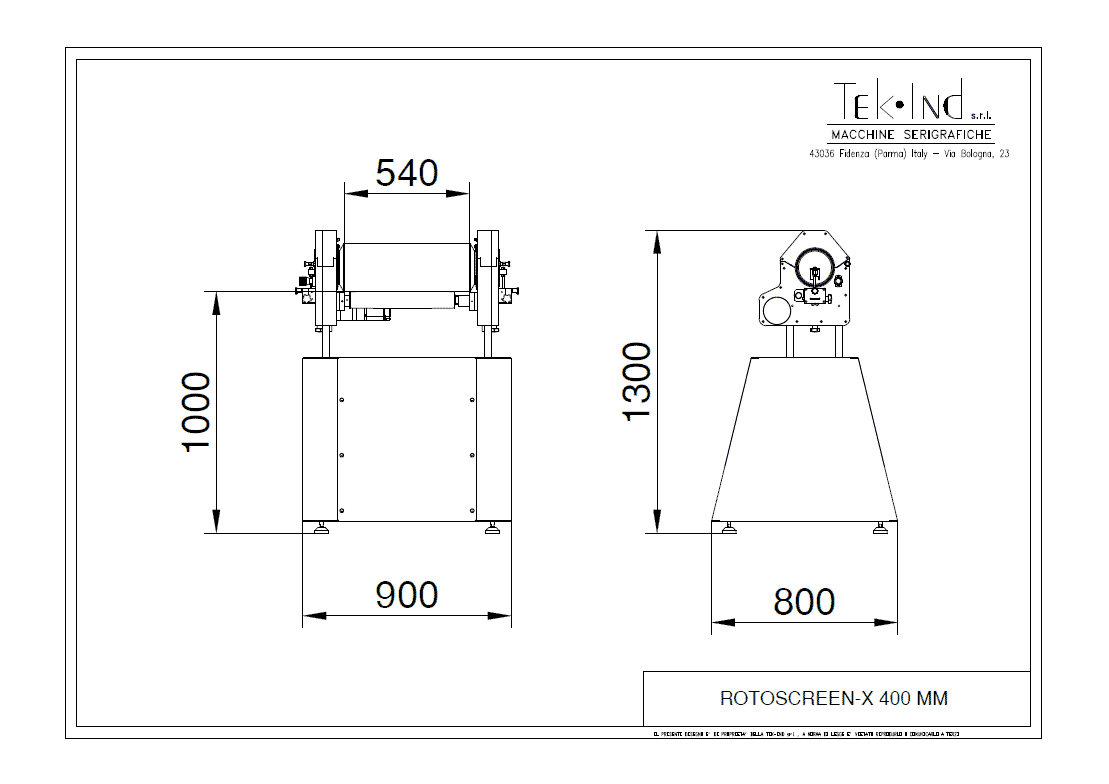

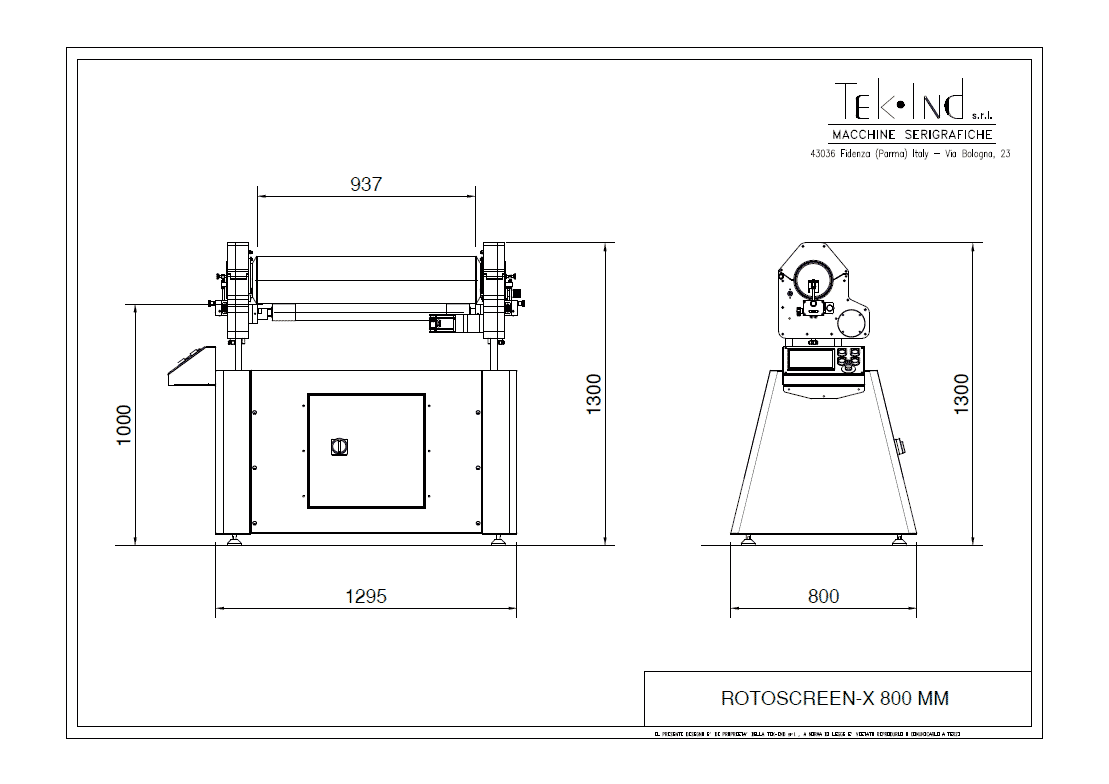

- External sizes (cm) Rotoscreen 400 (900 mm x 800 mm x 1300 mm) (WxLxH) Rotoscreen 800 (1300 mm x 800 mm x 1300 mm) (WxLxH)

- Usable inks Water base inks, plastisol inks, silicones

- Complementary Equipment Introduction(INT-01), dryer(Delta), guided exit(EXT-01), Silicon Pump (SP-series)