Delta

Small electric oven with infrared radiators

Machines > Dryers > Delta

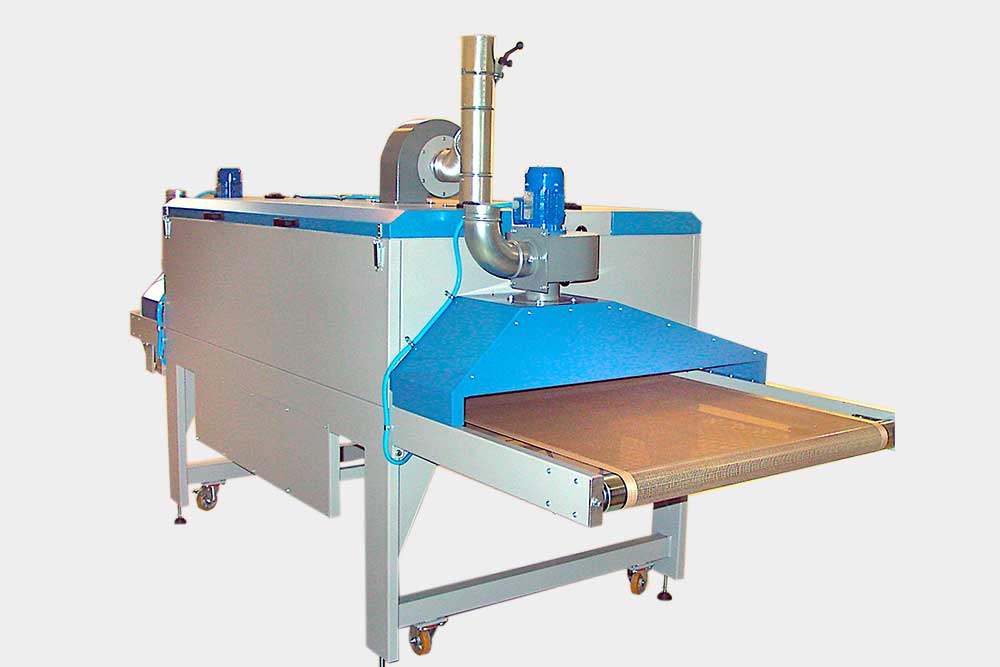

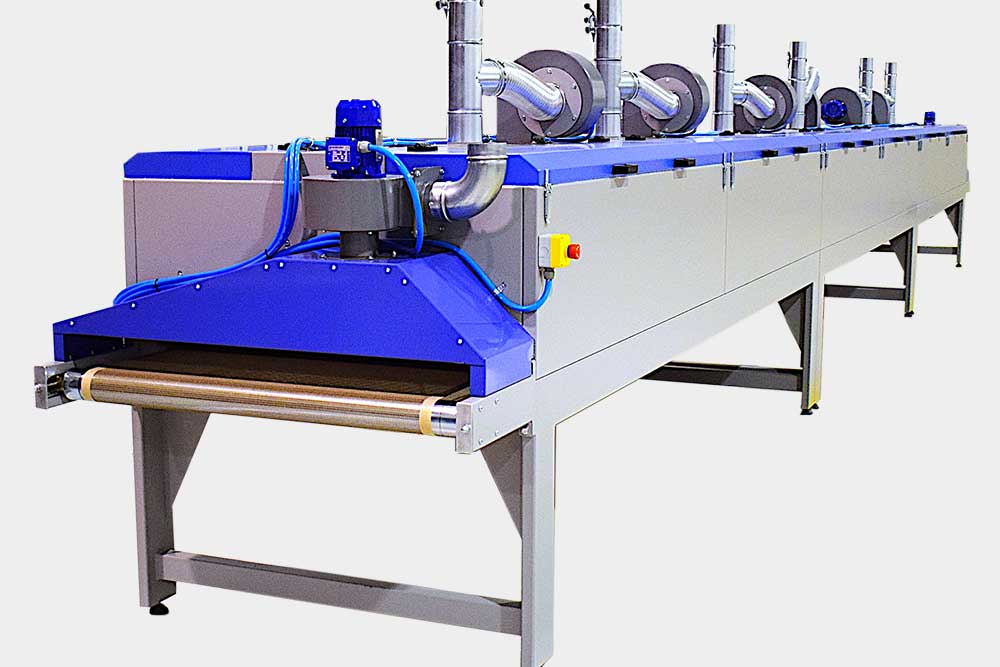

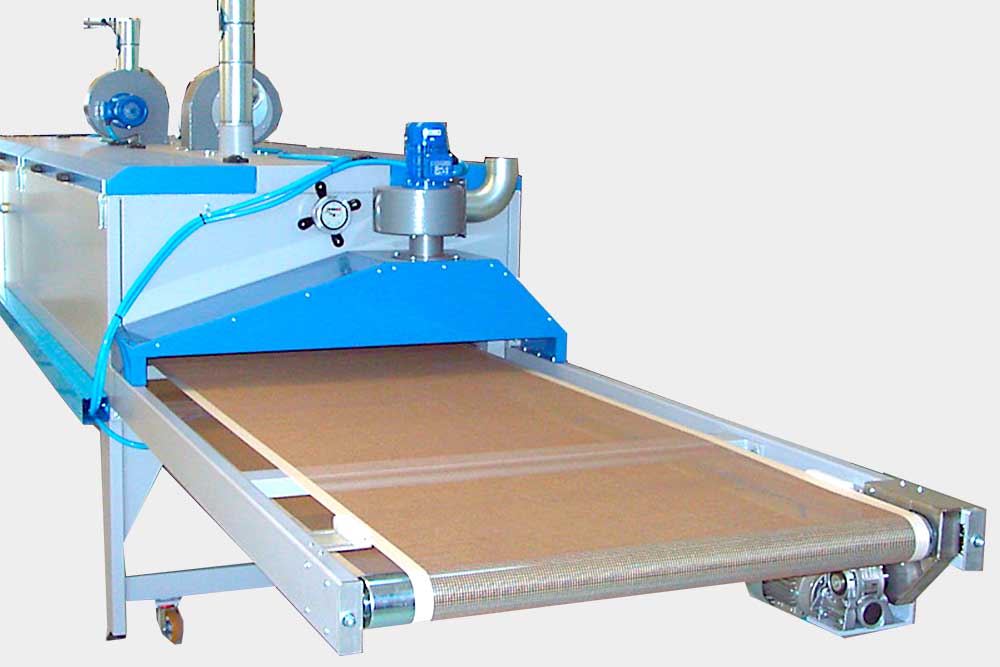

Small sized electrical dryer with ceramic Infra-Red radiators ideal to cure textile plastisol inks. The substrate is transported by means of a teflon belt controlled by inverter and resistant to high temperatures. Delta can be suitable also for drying Digital water-based inks.

MAIN TECHNICAL FEATURES

- Ceramic Infra-Red panels: The ceramic infra-red technique consists in using ceramic fiber panels crossed by electrical resistances as heat source.

- The infra-red do not emit light but only heat in the form of long-wave infra-red rays.

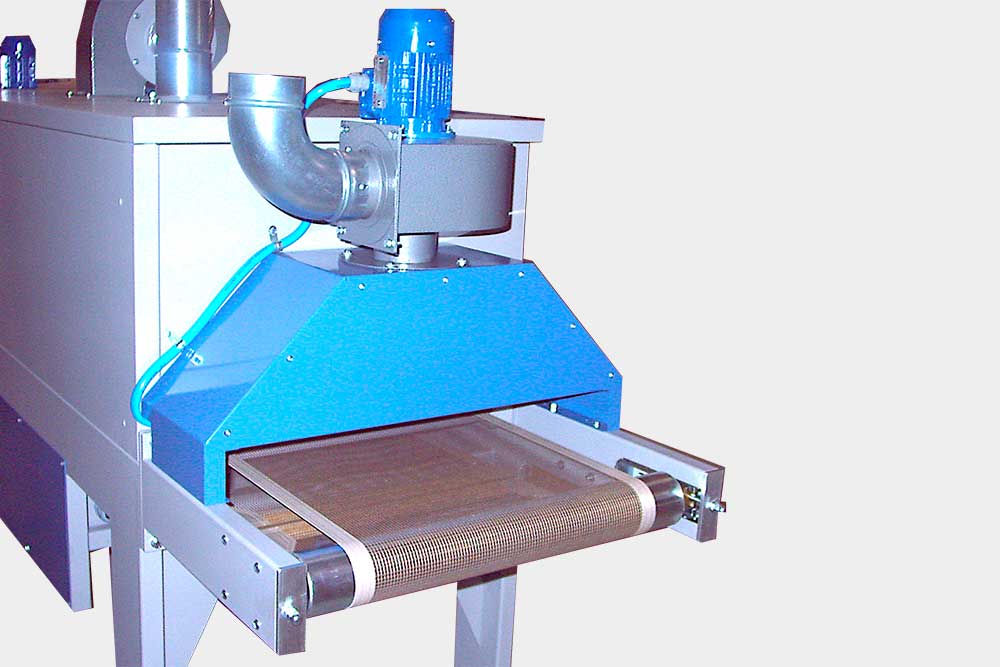

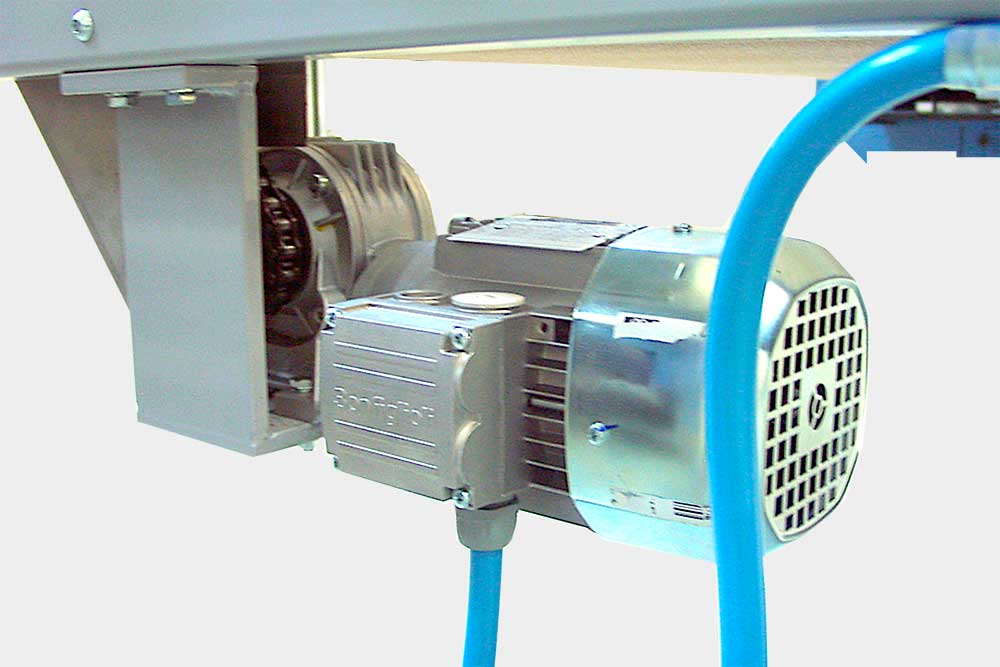

- Conveyor belt: The conveyor belt is made in special teflon fabrics resisting up to 200 °C. Its speed is controlled by inverter.

- The low thermal inertia allows temperature to increase quickly

- Possibility of height adjustment of the radiant panels.

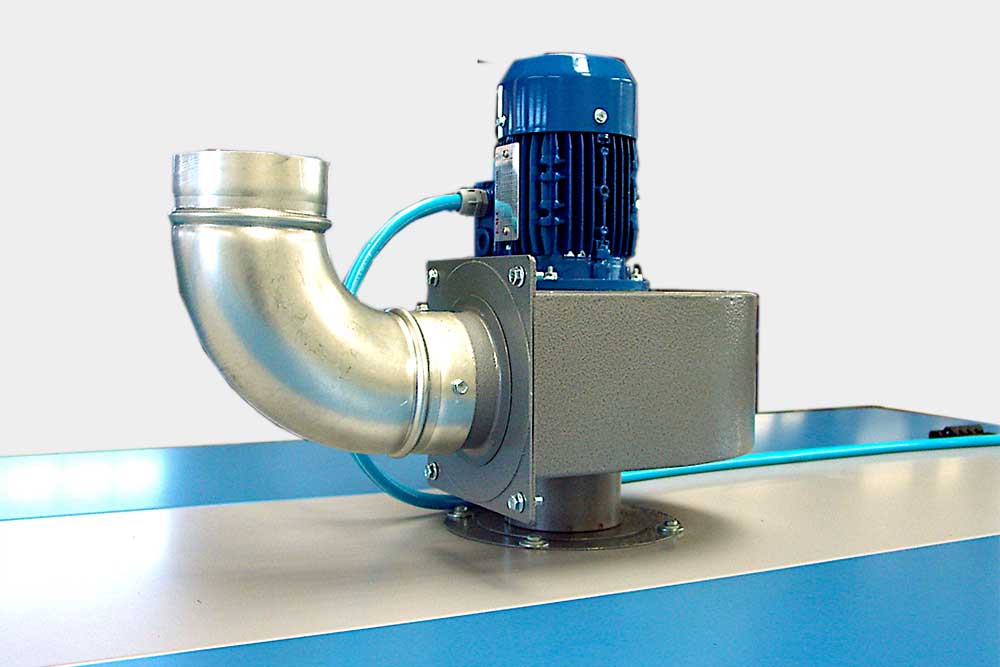

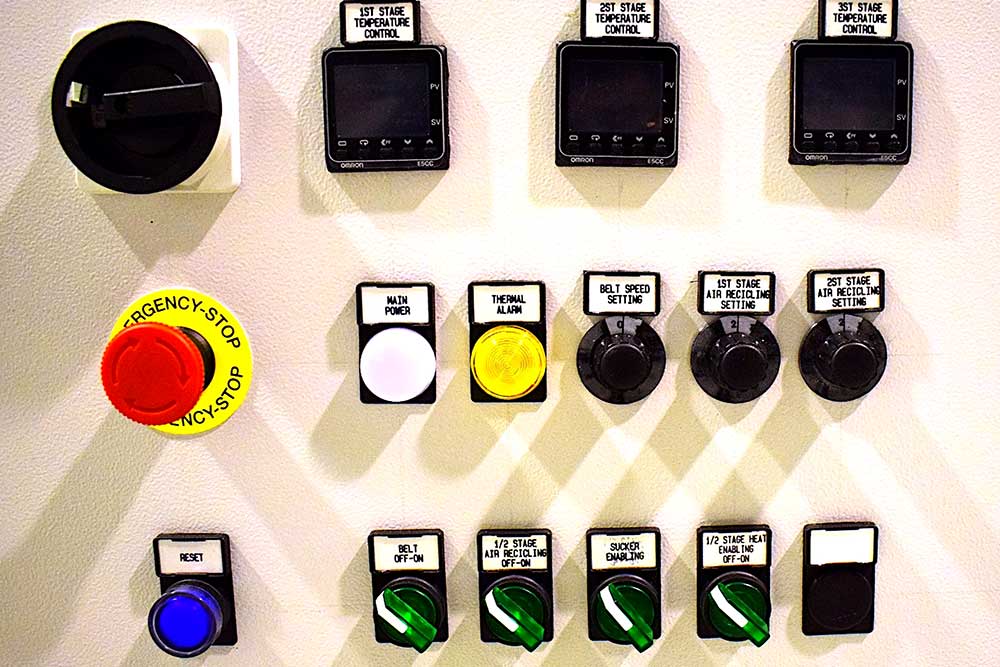

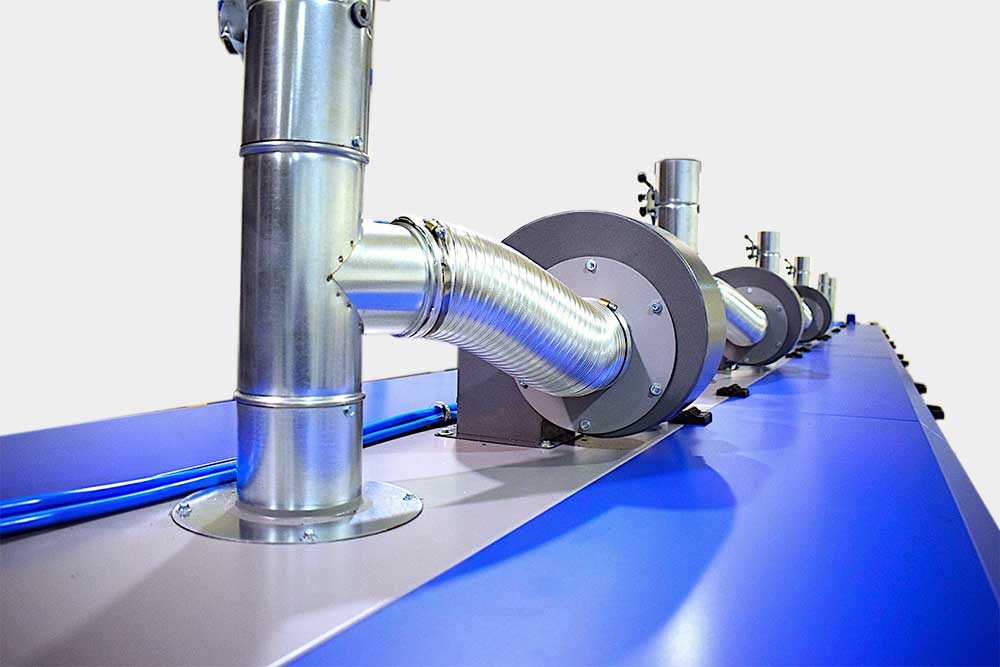

- Integrated ventilation with by-pass that allows the extraction or recirculation of air inside the dryer.

- Inlet and outlet hoods for fume extraction.

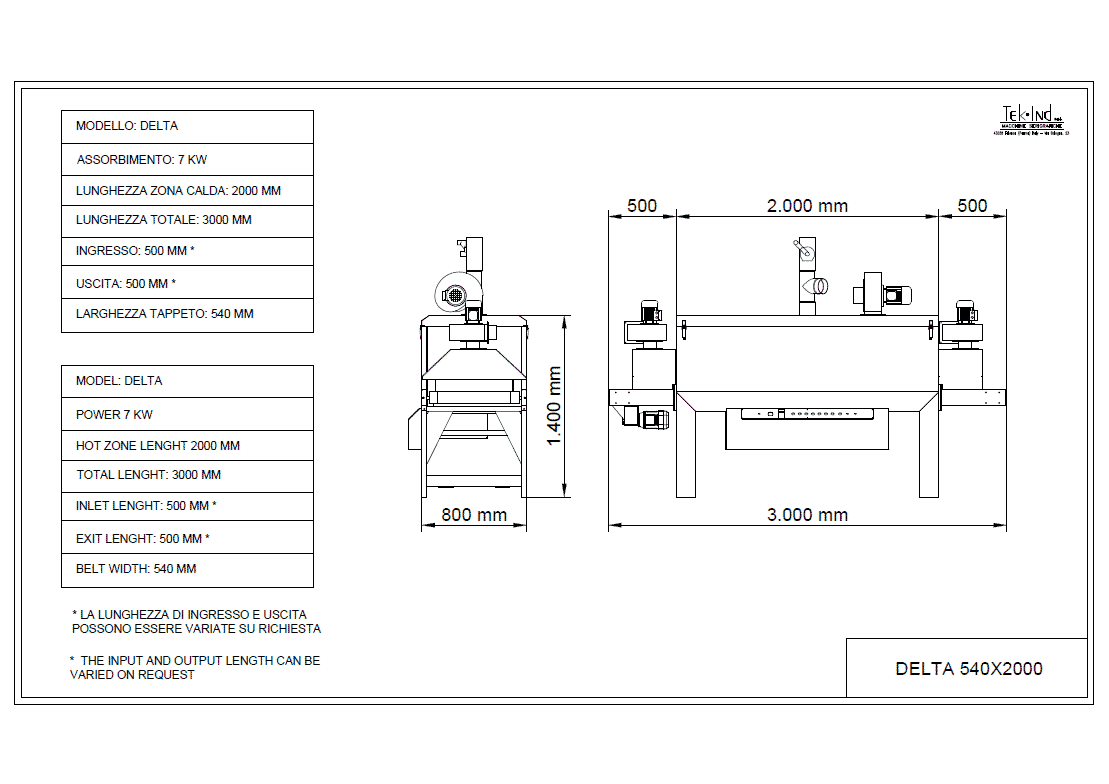

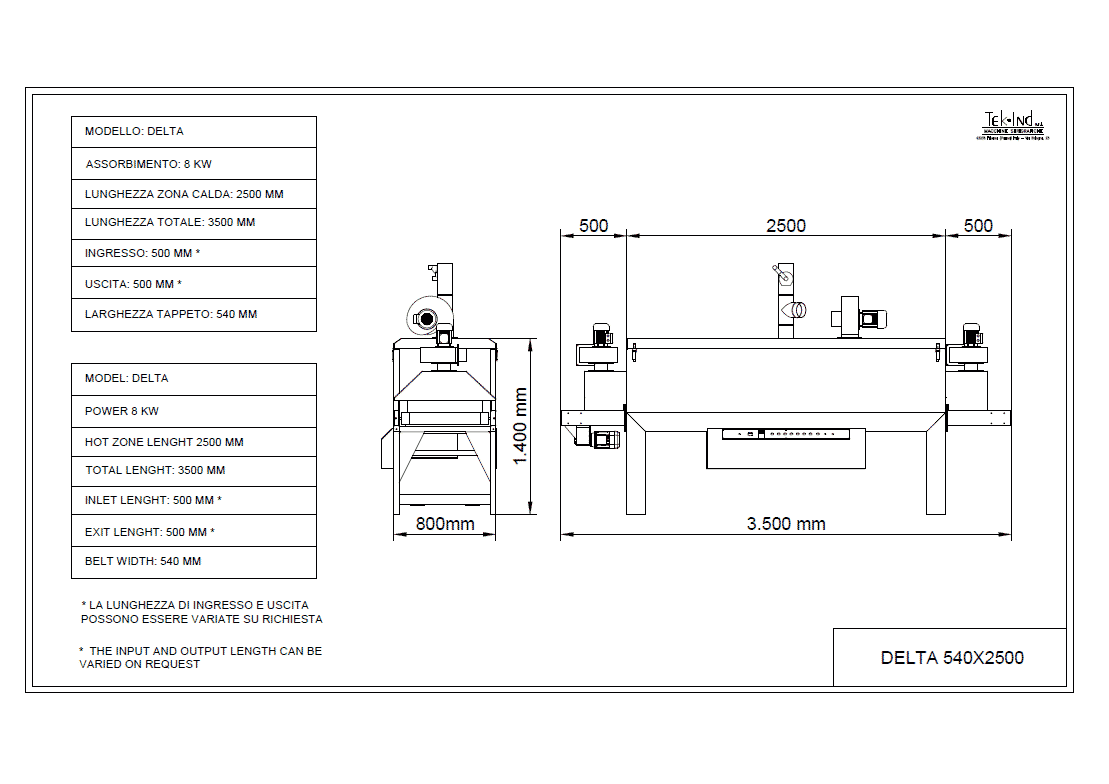

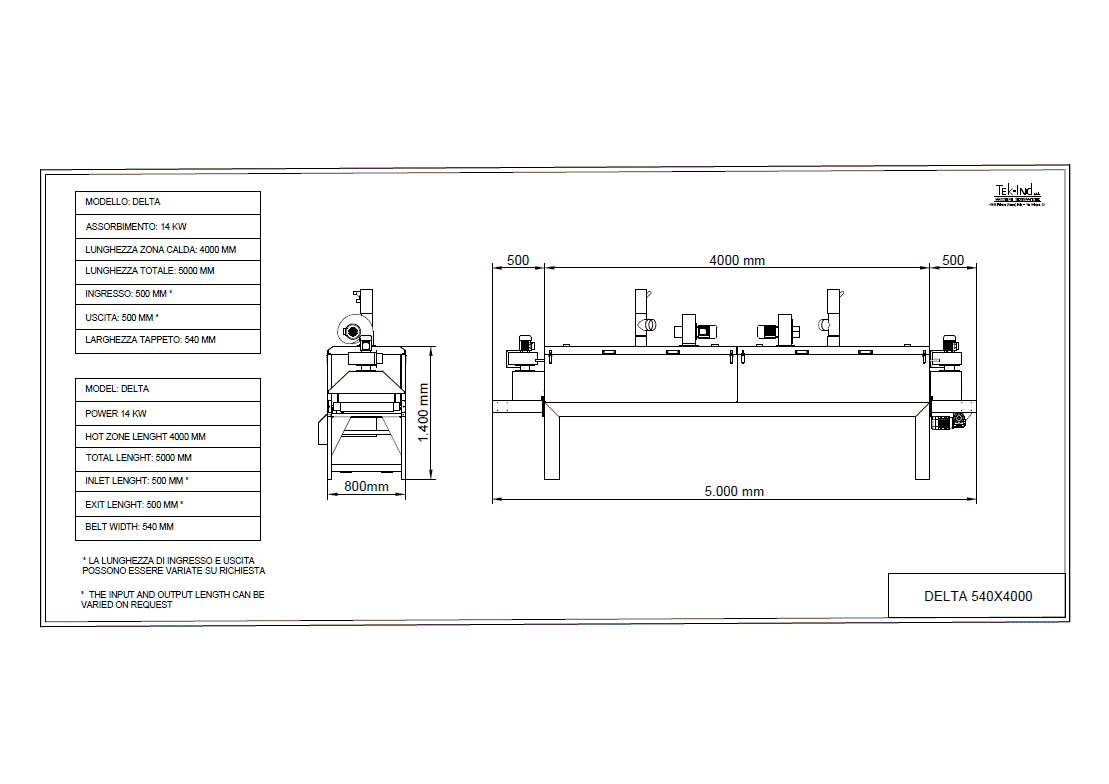

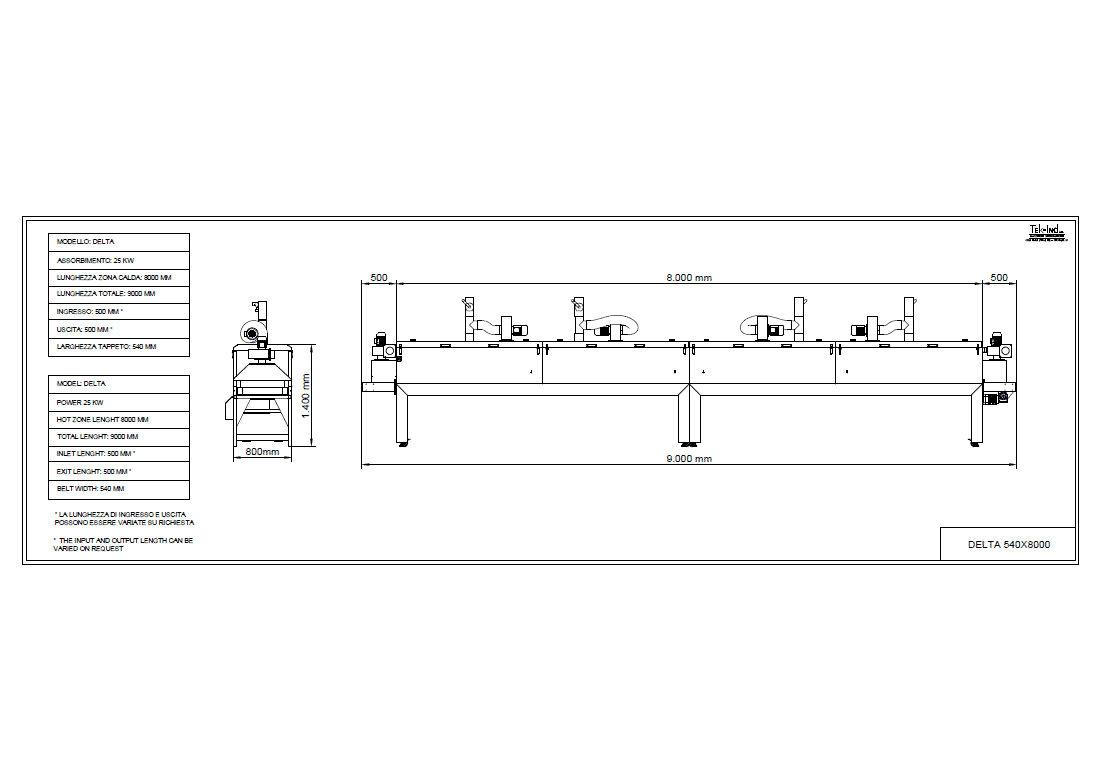

- Hot zone lenght: 2000 mm, 2500 mm, 4000 mm, 8000 mm, 12000 mm

- Belt width: 540 mm, 1050 mm, 1500 mm, 1800 mm

- Inlet lenght: 500 mm, 900 mm, 1200 mm, 1500 mm, 1700 mm, 2000 mm

- Outlet lenght: 500 mm, 900 mm, 1200 mm, 1500 mm, 1700 mm, 2000 mm

Available Model

| Belt Width | Hot Zone Lenght | Totale Dryer Width | Total Dryer Lenght * | Power (KW) | |

|---|---|---|---|---|---|

| Delta IR 540x2000 | 540 mm | 2000 mm | 800 mm | 3000 mm | 7 Kw |

| Delta IR 540x2500 | 540 mm | 2500 mm | 800 mm | 3500 mm | 8 Kw |

| Delta IR 540x4000 | 540 mm | 4000 mm | 800 mm | 5000 mm | 14 Kw |

| Delta IR 540x8000 | 540 mm | 8000 mm | 800 mm | 9000 mm | 25 Kw |

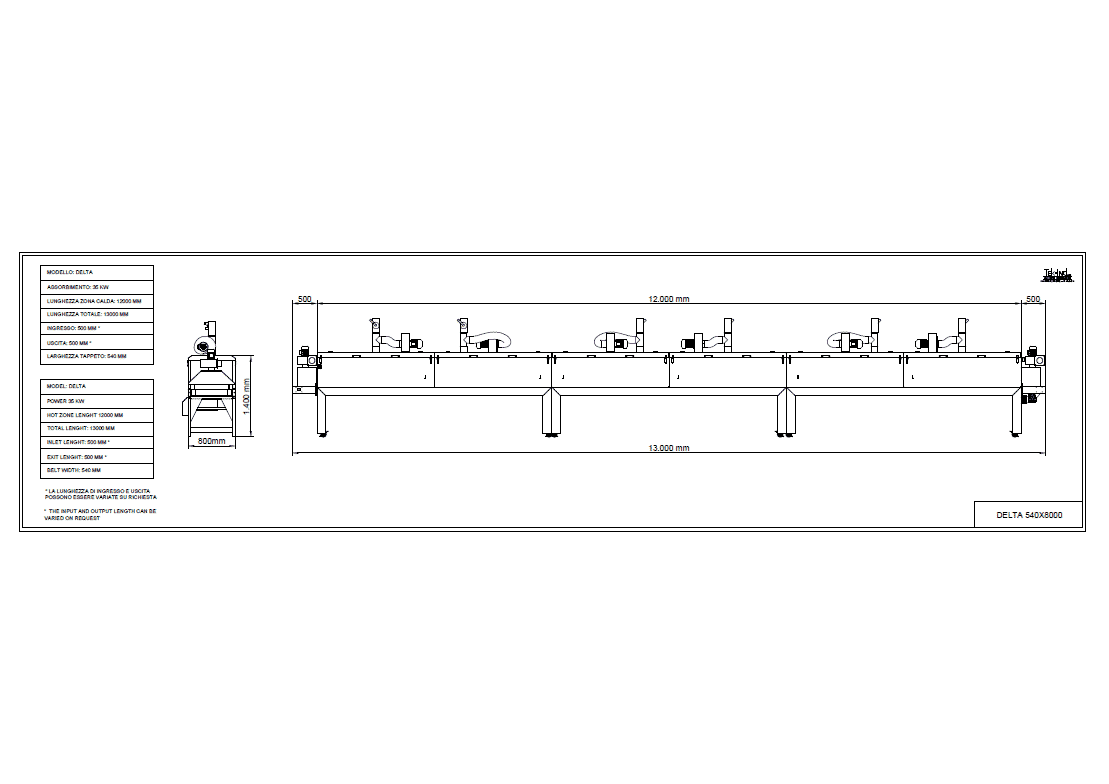

| Delta IR 540x12000 | 540 mm | 12000 mm | 800 mm | 13000 mm | 35 Kw |

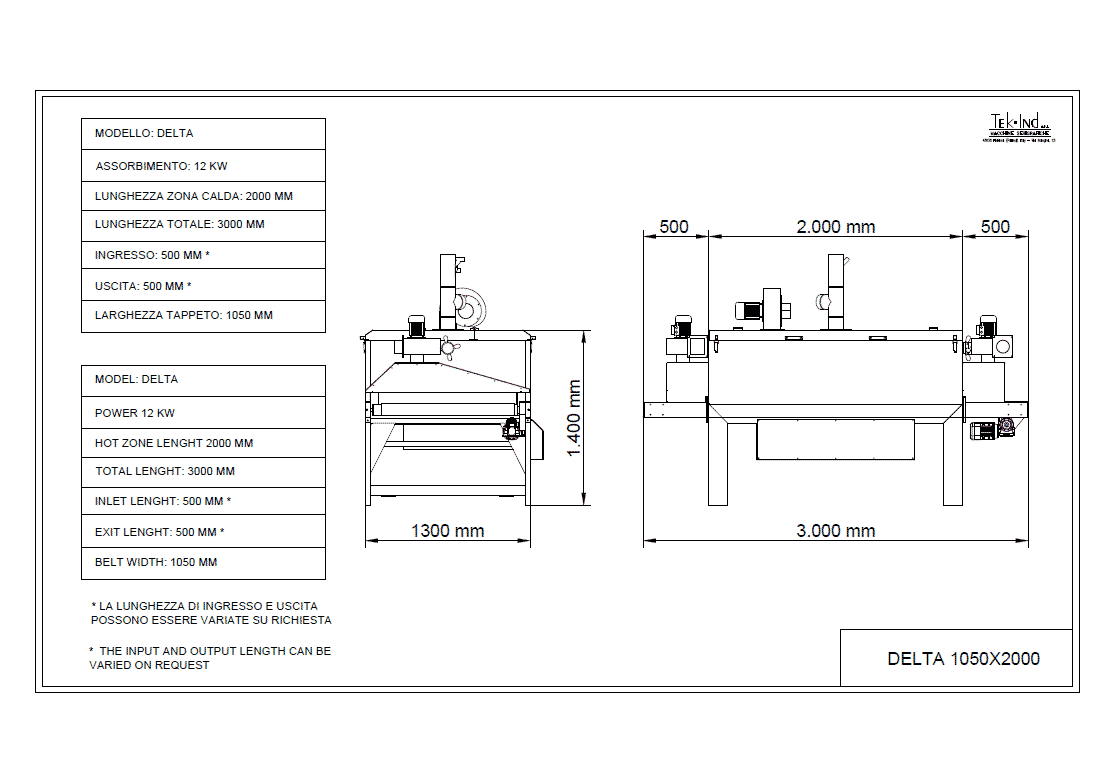

| Delta IR 1050x2000 | 1050 mm | 2000 mm | 1300 mm | 3000 mm | 12 Kw |

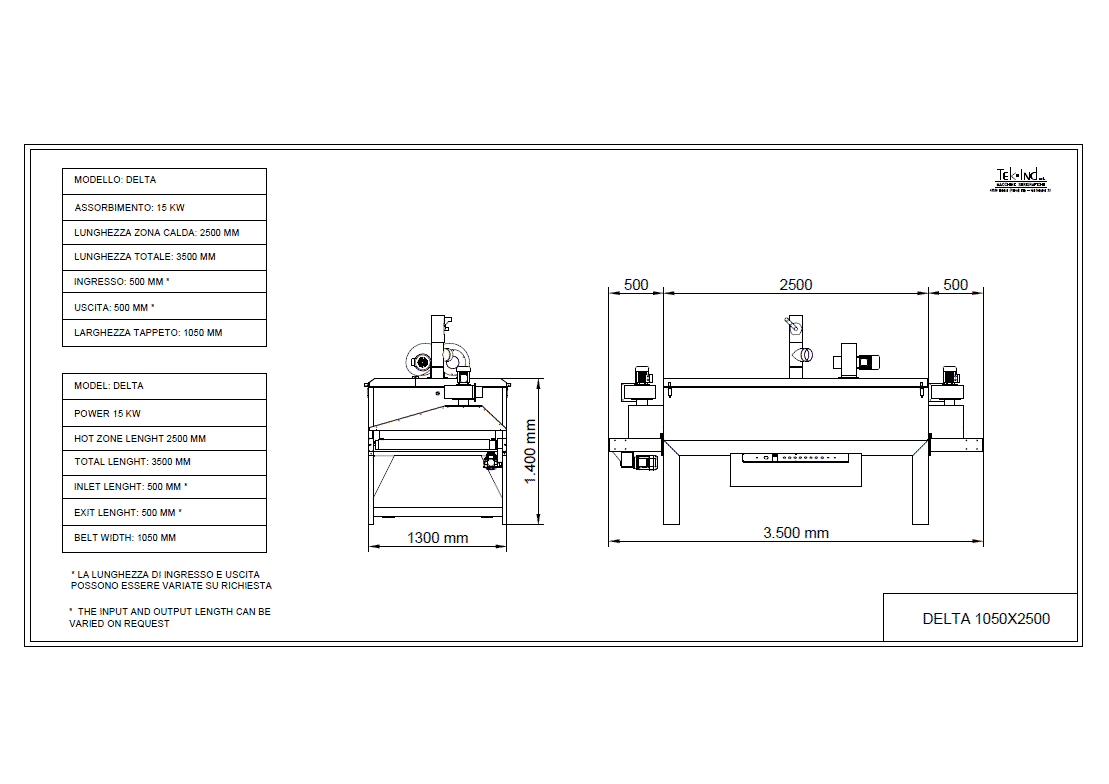

| Delta IR 1050x2500 | 1050 mm | 2500 mm | 1300 mm | 3500 mm | 15 Kw |

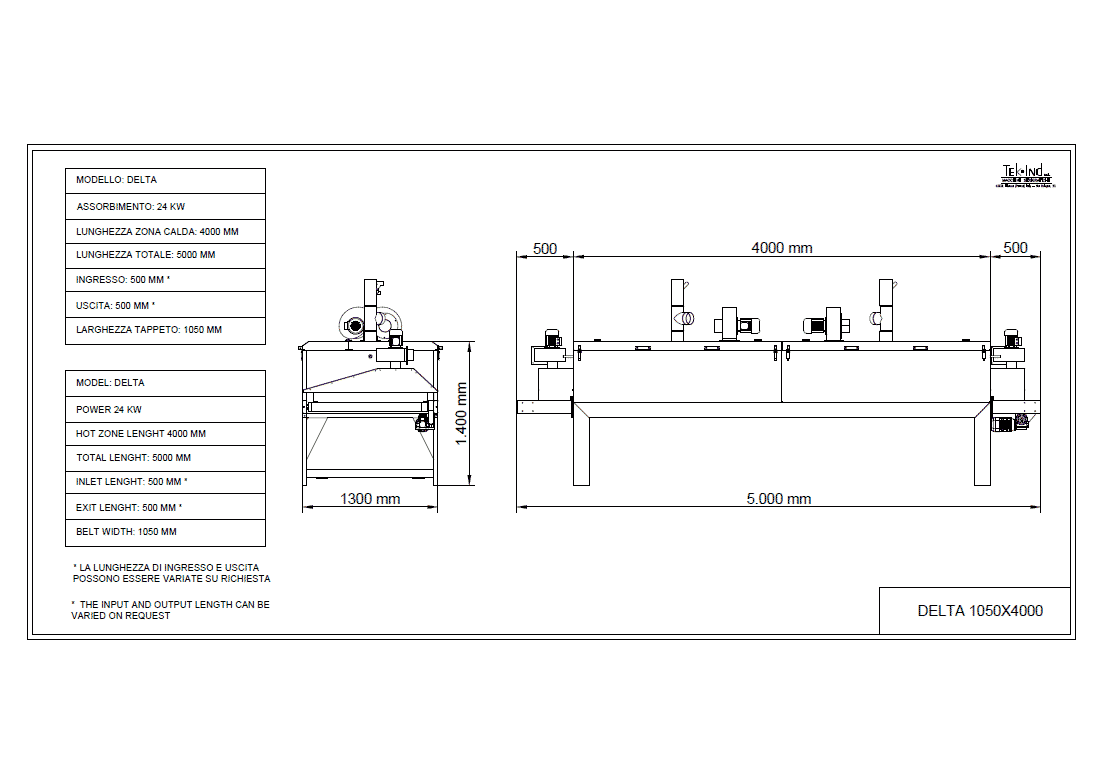

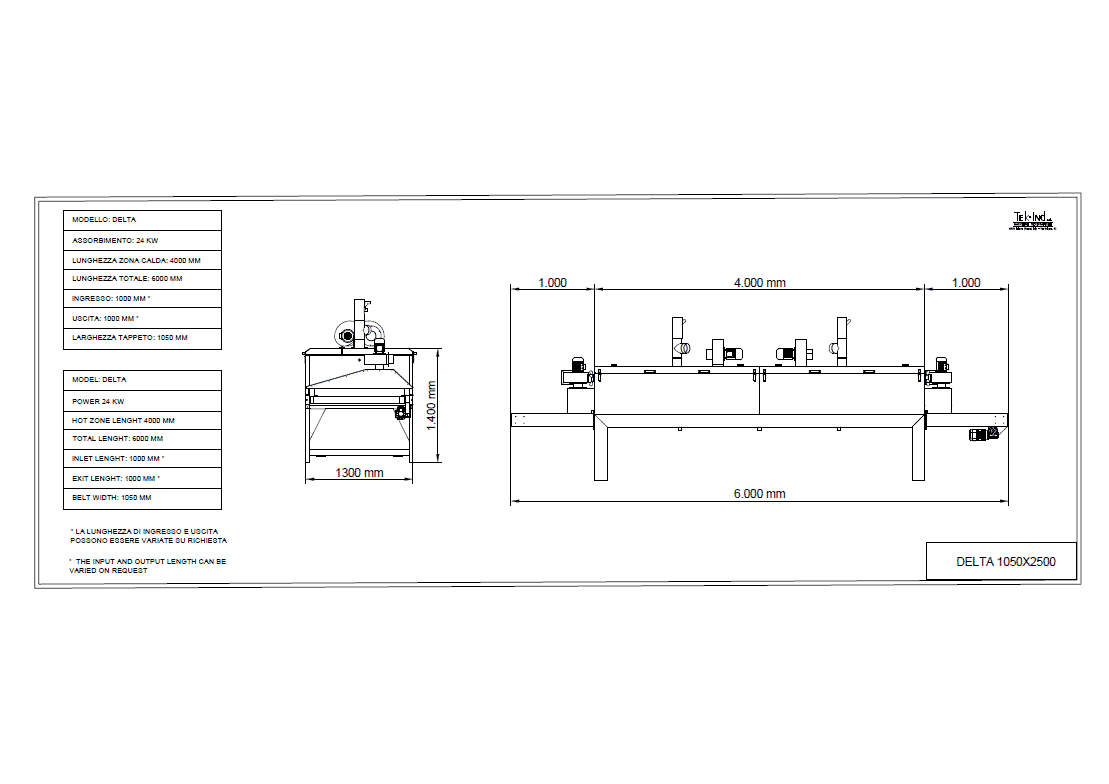

| Delta IR 1050x4000 | 1050 mm | 4000 mm | 1300 mm | 5000 mm | 24 Kw |

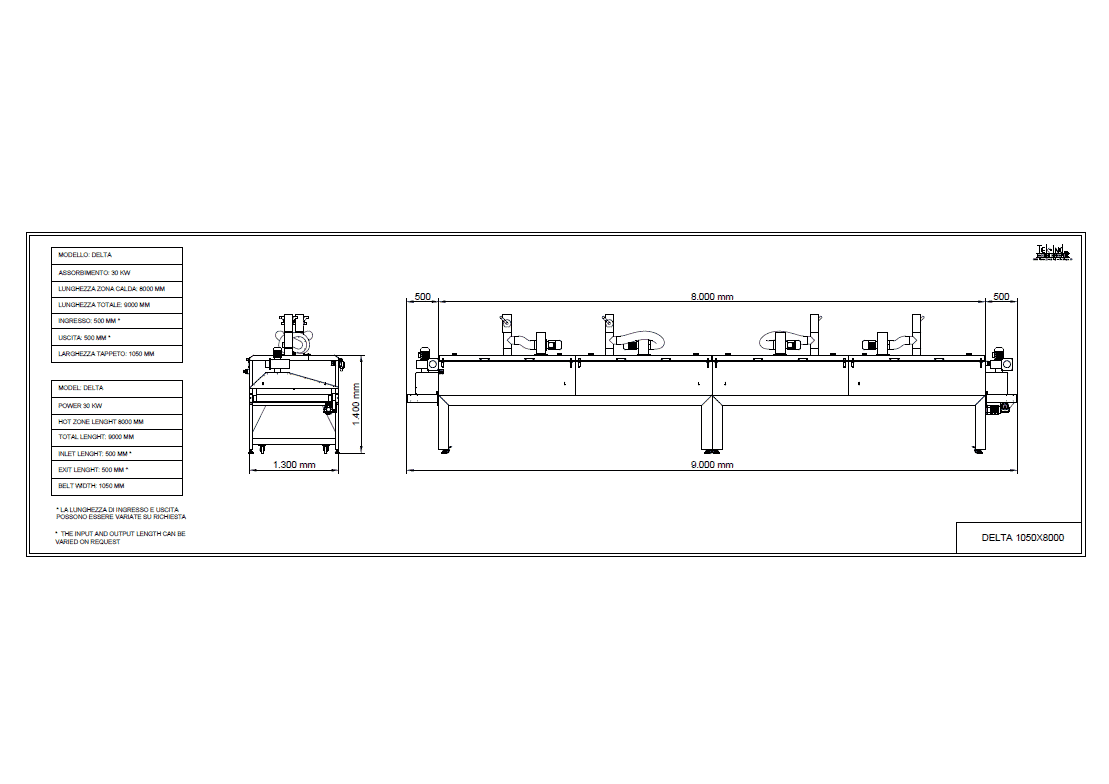

| Delta IR 1050x8000 | 1050 mm | 8000 mm | 1300 mm | 9000 mm | 30 Kw |

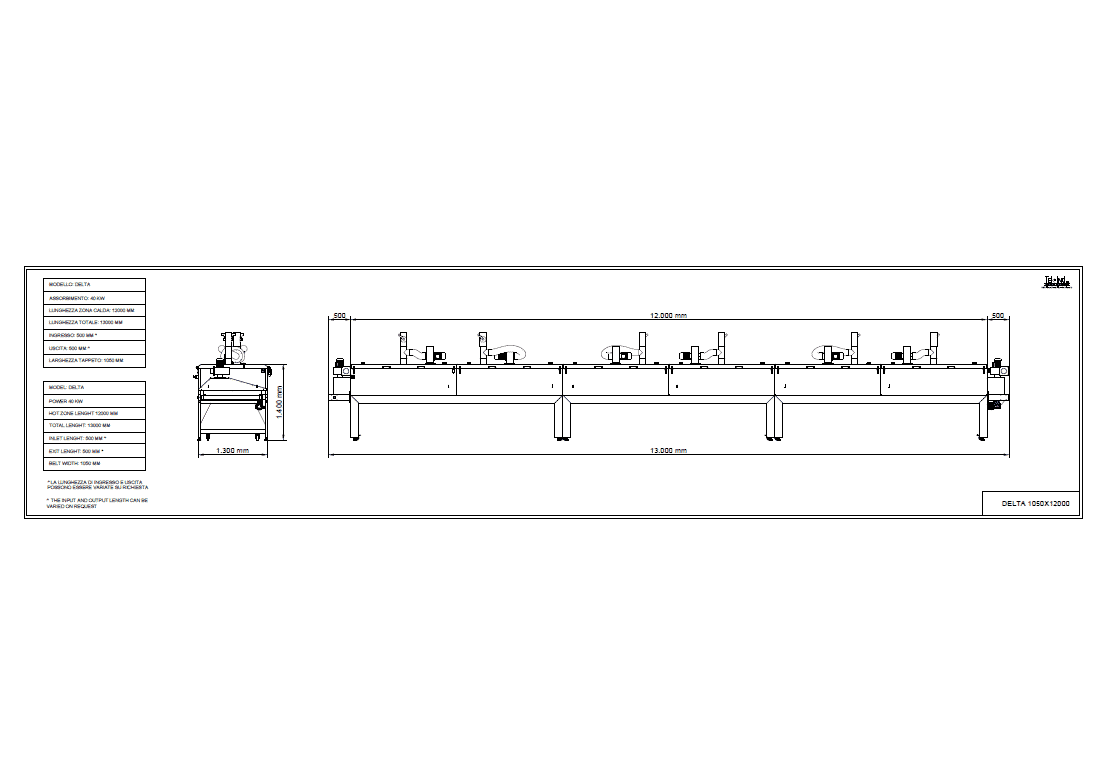

| Delta IR 1050x12000 | 1050 mm | 12000 mm | 1300 mm | 13000 mm | 40 Kw |

| Delta IR 1500x2000 | 1500 mm | 2000 mm | 1750 mm | 3000 mm | 16 Kw |

| Delta IR 1500x2500 | 1500 mm | 2500 mm | 1750 mm | 3500 mm | 22 Kw |

| Delta IR 1500x4000 | 1500 mm | 4000 mm | 1750 mm | 5000 mm | 30 Kw |

| Delta IR 1500x8000 | 1500 mm | 8000 mm | 1750 mm | 9000 mm | 50 Kw |

| Delta IR 1500x12000 | 1500 mm | 12000 mm | 1750 mm | 13000 mm | 60 Kw |

| Delta IR 1800x2000 | 1800 mm | 2000 mm | 2050 mm | 3000 mm | 20 Kw |

| Delta IR 1800x2500 | 1800 mm | 2500 mm | 2050 mm | 3500 mm | 25 Kw |

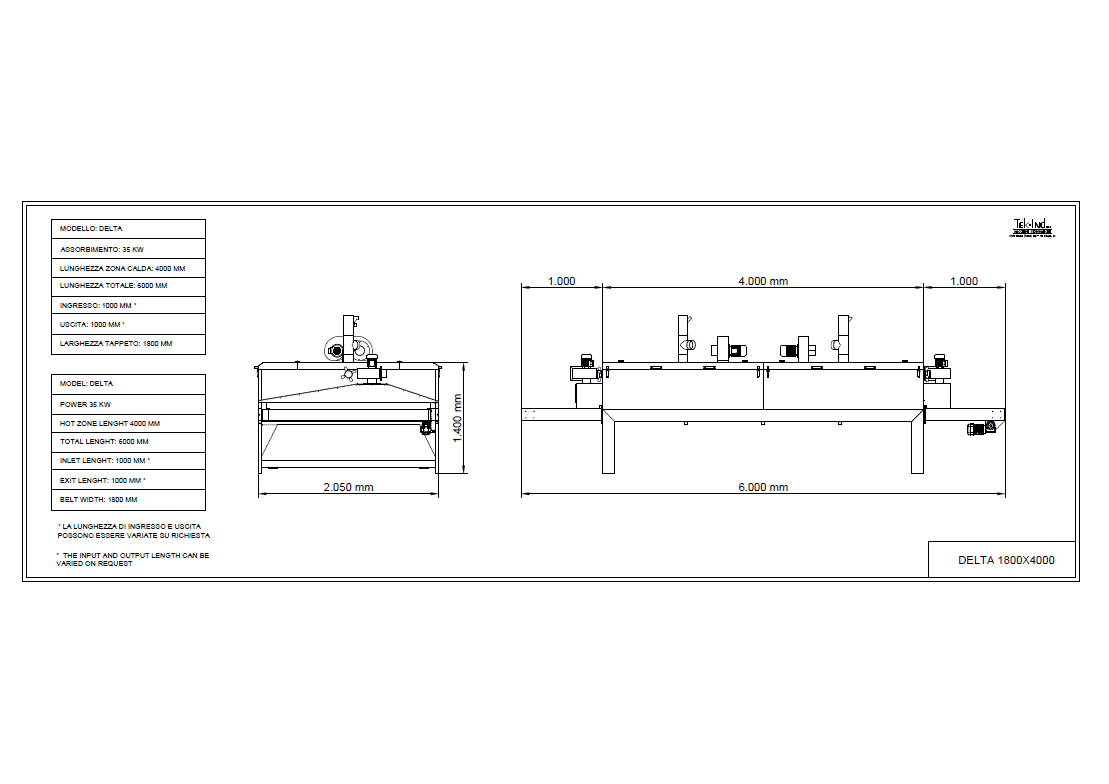

| Delta IR 1800x4000 | 1800 mm | 4000 mm | 2050 mm | 5000 mm | 35 Kw |

| Delta IR 1800x8000 | 1800 mm | 8000 mm | 2050 mm | 9000 mm | 65 Kw |

| Delta IR 1800x12000 | 1800 mm | 12000 mm | 2050 mm | 13000 mm | 85 Kw |

* Total length calculated for minimum inlet and outlet lenght: 500 mm + 500 mm, when the inlet and outlet lengths differ from 500 mm + 500 mm, the total dryer length will be:

Hot zone length + Entrance Length + Exit Lenght

When the oven is to be combined with narrow fabric printing machine, a long introduction is not necessary, the minimum is sufficient, for other applications a customer discretion the choice of the lengths of the entrance and exit of the oven, a minimum input of 900 mm is recommended or better 1200 mm for combination with automatic circular machines to facilitate loading and unloading operations.

Hot zone length + Entrance Length + Exit Lenght

When the oven is to be combined with narrow fabric printing machine, a long introduction is not necessary, the minimum is sufficient, for other applications a customer discretion the choice of the lengths of the entrance and exit of the oven, a minimum input of 900 mm is recommended or better 1200 mm for combination with automatic circular machines to facilitate loading and unloading operations.