SP Pump

Ink pump for silicone

Machines > Narrow Fabric Solution > SP Pump

SP-Pump 05

Gear pump for mixing bi-component silicone, suitable for mixing 5 kg of component A + 5 kg of component B. The 5 kg tanks can be filled manually using a spatula or automatically using an external pneumatic pump to be able to pass from drums of 200Kg or 20 kg to the 5 kg container that can be loading into the machine. Mixing ratios from 1: 1 to 10: 1 can be managed. With SP-Pump 5, it is possible to make only prints with transparent silicone, to colour the silicones it is necessary a further pump that previously mix the white silicone with pigment. The displacement of the gear pumps available can vary from 0.1 cc / rev up to a maximum of 7 cc / rev. The various displacements guarantee precise and correct dosages starting from 0.2 up to 400 cc / minute. Three-phase asynchronous motors drive the gear pumps.

Gear pump for mixing bi-component silicone, suitable for mixing 5 kg of component A + 5 kg of component B. The 5 kg tanks can be filled manually using a spatula or automatically using an external pneumatic pump to be able to pass from drums of 200Kg or 20 kg to the 5 kg container that can be loading into the machine. Mixing ratios from 1: 1 to 10: 1 can be managed. With SP-Pump 5, it is possible to make only prints with transparent silicone, to colour the silicones it is necessary a further pump that previously mix the white silicone with pigment. The displacement of the gear pumps available can vary from 0.1 cc / rev up to a maximum of 7 cc / rev. The various displacements guarantee precise and correct dosages starting from 0.2 up to 400 cc / minute. Three-phase asynchronous motors drive the gear pumps.

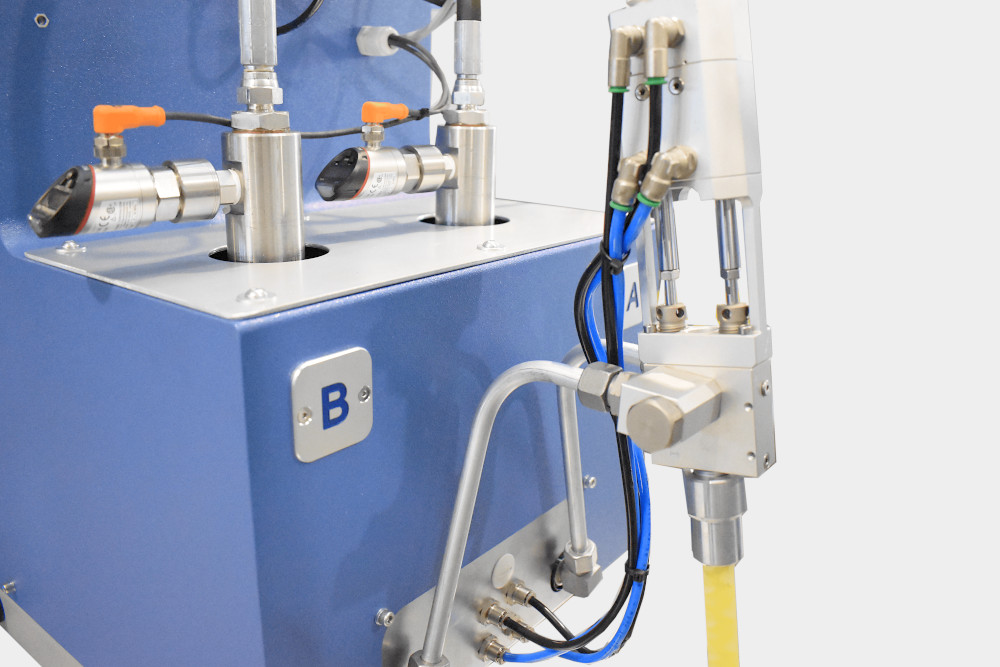

SP-Pump - Silicone pigment dispenser

SP-Pump - is a silicone-based pigment dispenser, can be combined with the SP-Pump 05 pump, this pump allows you to dose pigments without interfering with the normal supply of two-component silicone, the pigment is combined with one of the components A / B just before the mixer, then replacing the mixer and the last part of the tube the original circuit returns as clean as the initial stage. It is possible to clean the system with Silicon Remouver, it is possible to load one color at a time. The plant is managed by PLC and the motor speed can be varied by an inverter, the pressure reading from [0–200 Bar] which occurs after the gear pump allows to feed the silicone with constant pressure. The gear pump allows you to adjust the amount of pigment from 0.2 cc / min to 22 cc / min.

SP-Pump - is a silicone-based pigment dispenser, can be combined with the SP-Pump 05 pump, this pump allows you to dose pigments without interfering with the normal supply of two-component silicone, the pigment is combined with one of the components A / B just before the mixer, then replacing the mixer and the last part of the tube the original circuit returns as clean as the initial stage. It is possible to clean the system with Silicon Remouver, it is possible to load one color at a time. The plant is managed by PLC and the motor speed can be varied by an inverter, the pressure reading from [0–200 Bar] which occurs after the gear pump allows to feed the silicone with constant pressure. The gear pump allows you to adjust the amount of pigment from 0.2 cc / min to 22 cc / min.

Model Features

| Model | work with: | Printing Type | Tank size: | Engine type: | Pressure | Installed power | Voltage | Size (L x W x H) |

|---|---|---|---|---|---|---|---|---|

| SP-Pump 5 | Rotoscreen US-01 Silicon Nozzle |

Rotative printing Silicone Stripes |

5kg + 5kg | asynchronous motor | 6-8 bar | 700 W | 230 V - F+T | 770x510x750 mm |

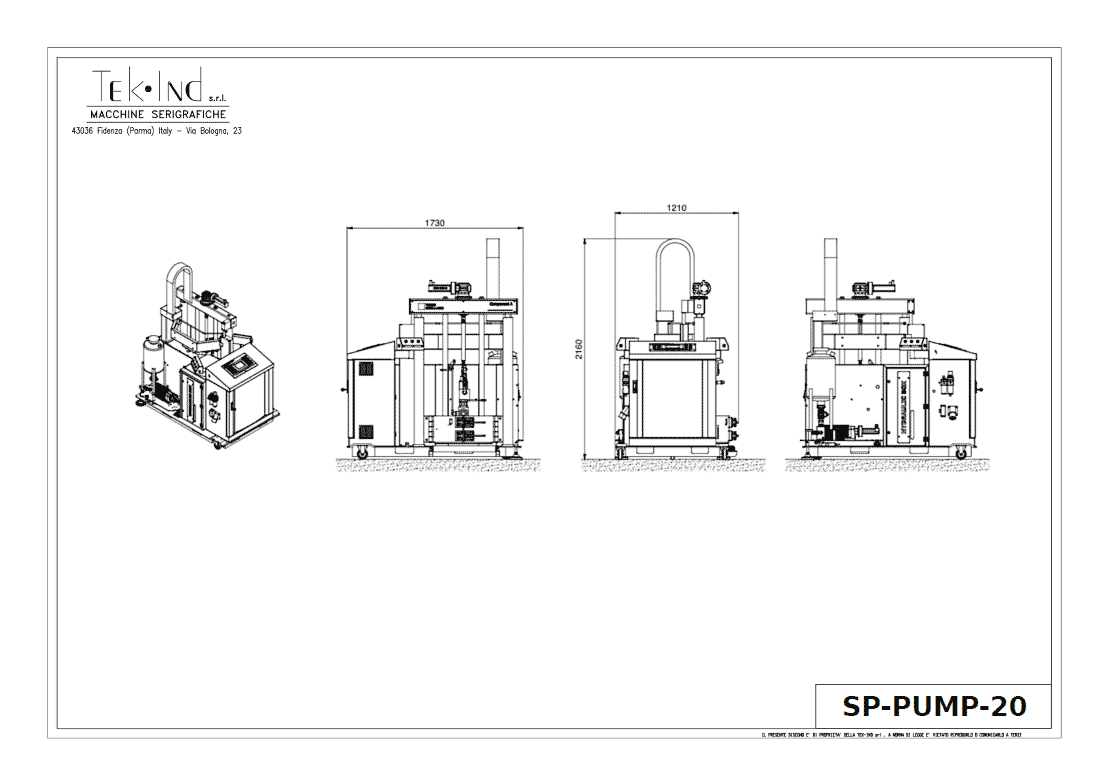

| SP-Pump 20 | Rotoscreen US-01 Silicon Nozzle |

Rotative printing Silicone Stripes |

20kg + 20kg | Brushless | 6-8 bar | 5000 W | 400 V - 3F+N+T | 2360x1180x1785 mm |

| SP-Pump 20-CL | Rotoscreen US-01 Silicon Nozzle |

Rotative printing Silicone Stripes |

20kg + 20kg + 6x2kg | Brushless | 6-8 bar | 5500 W | 400 V - 3F+N+T | 1700x1200x2100 mm |

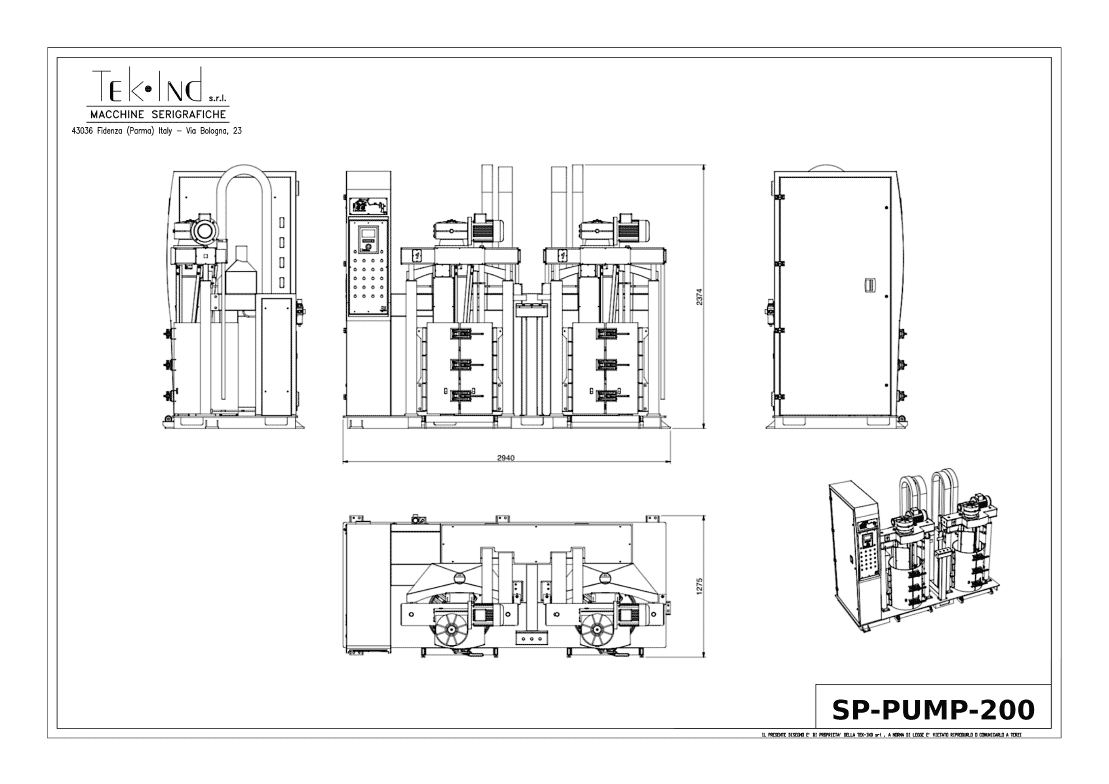

| SP-Pump 200 | Rotoscreen US-01 Silicon Nozzle |

Rotative printing Silicone Stripes |

200kg + 200kg | Brushless | 6-8 bar | 5500 W | 400 V - 3F+N+T | 1550x3050x2100 mm |

| SP-Pump Silicone pigment dispenser |

SP-Pump-05 | pigment dispenser | 1kg | asynchronous motor | 6-8 bar | 400 W | 230 V - F+T | 200x400x500 mm |