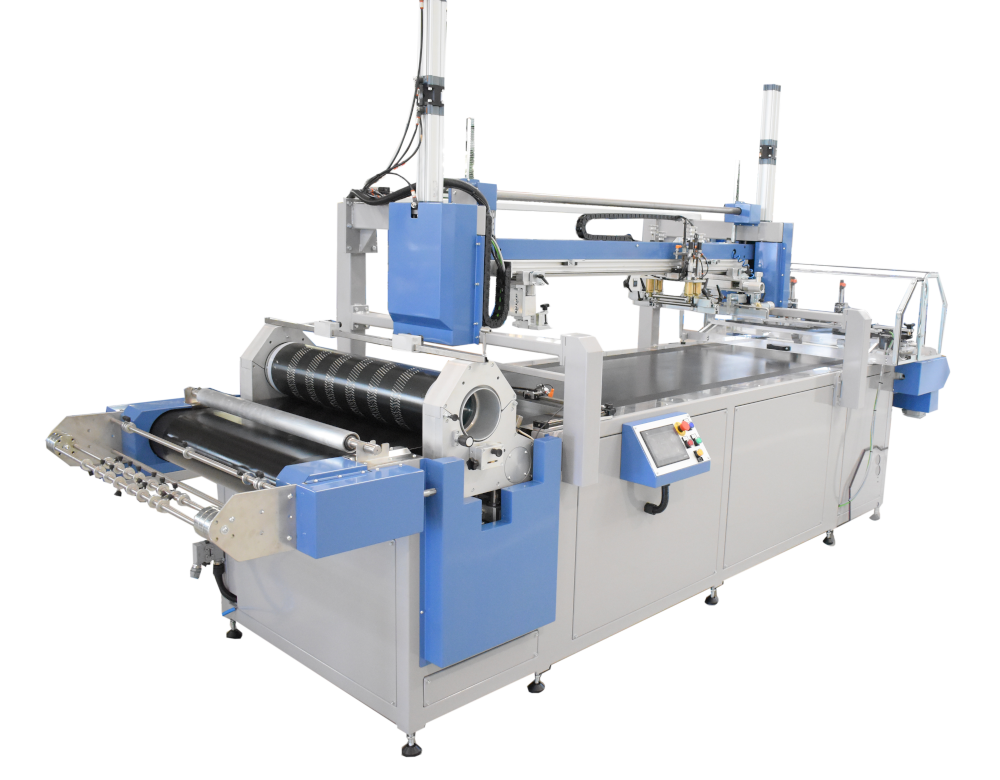

GA-1 - NF

Screen-printing color + 1 Rotary color

Machines > Narrow Fabric Solution > GA-1 - NF

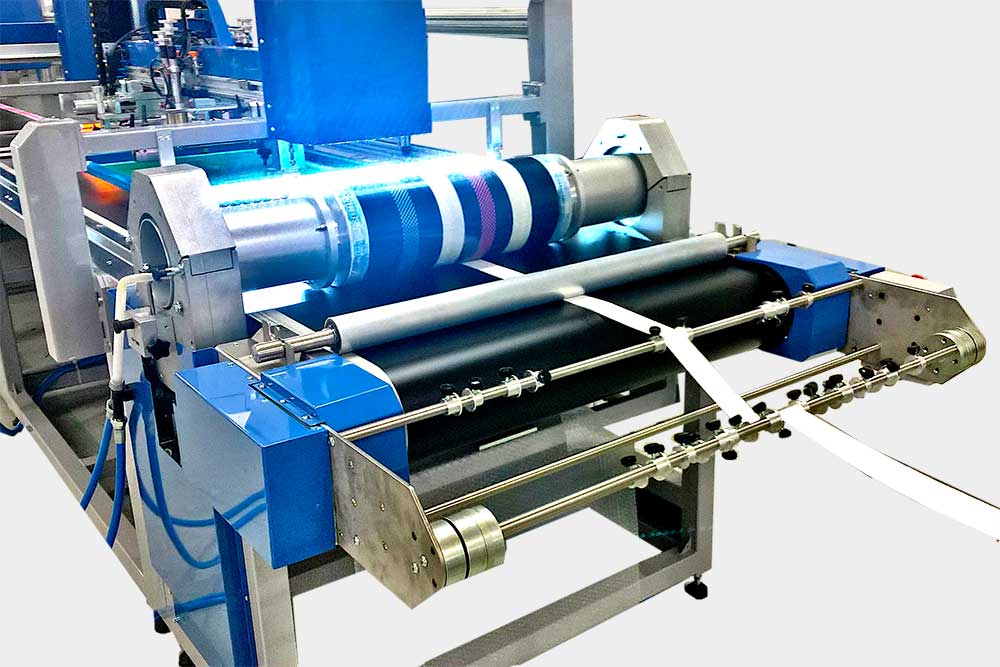

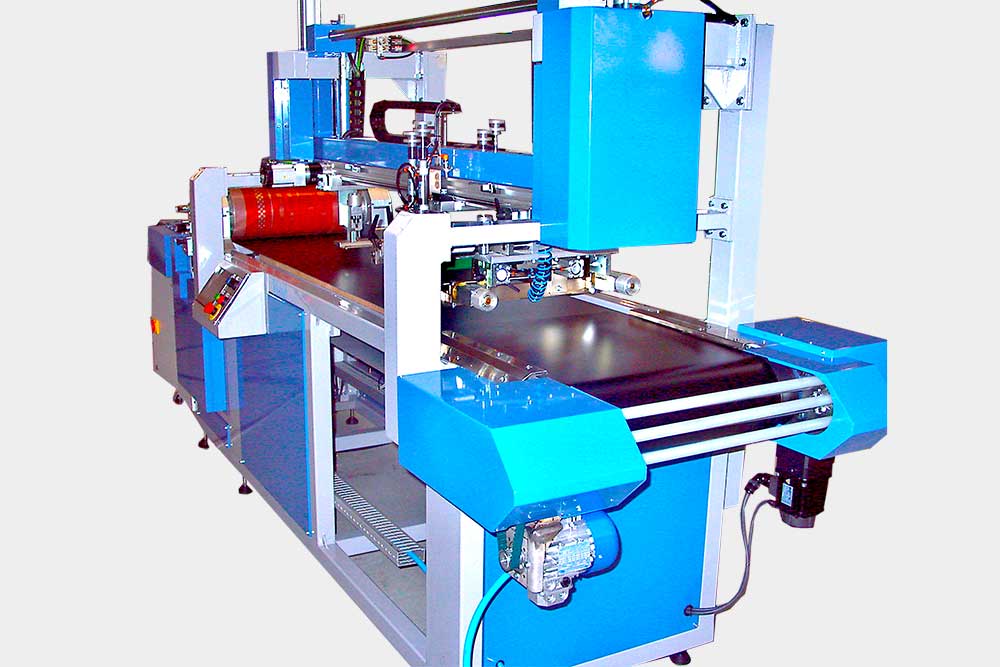

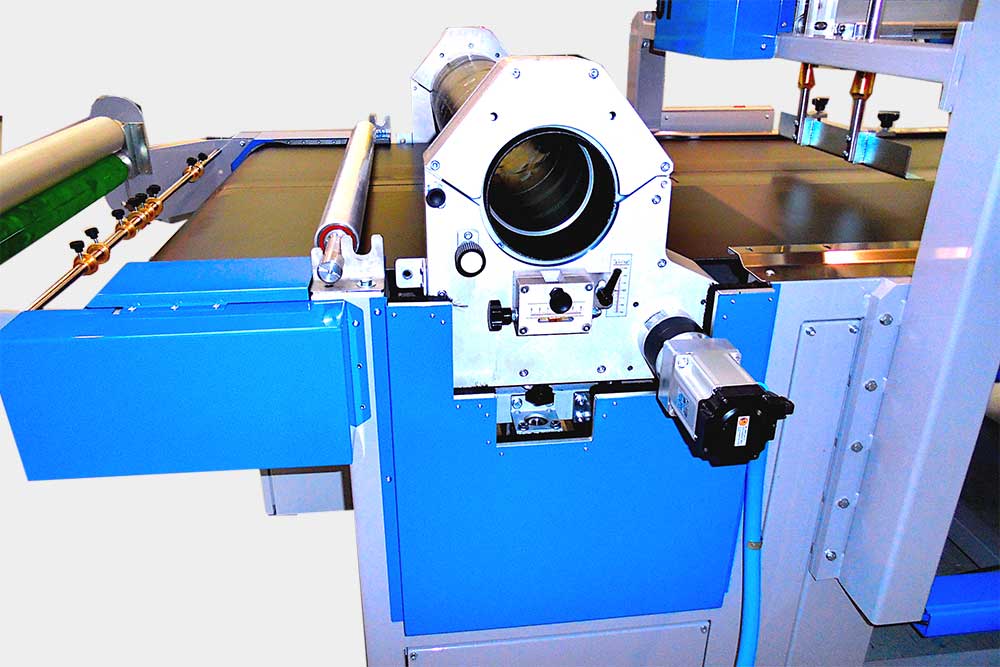

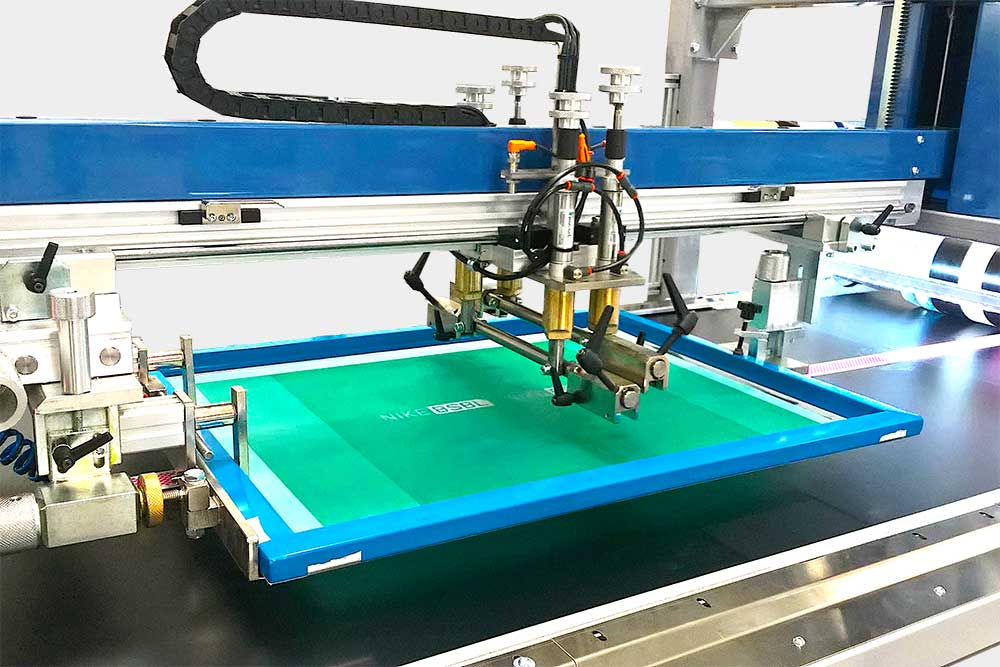

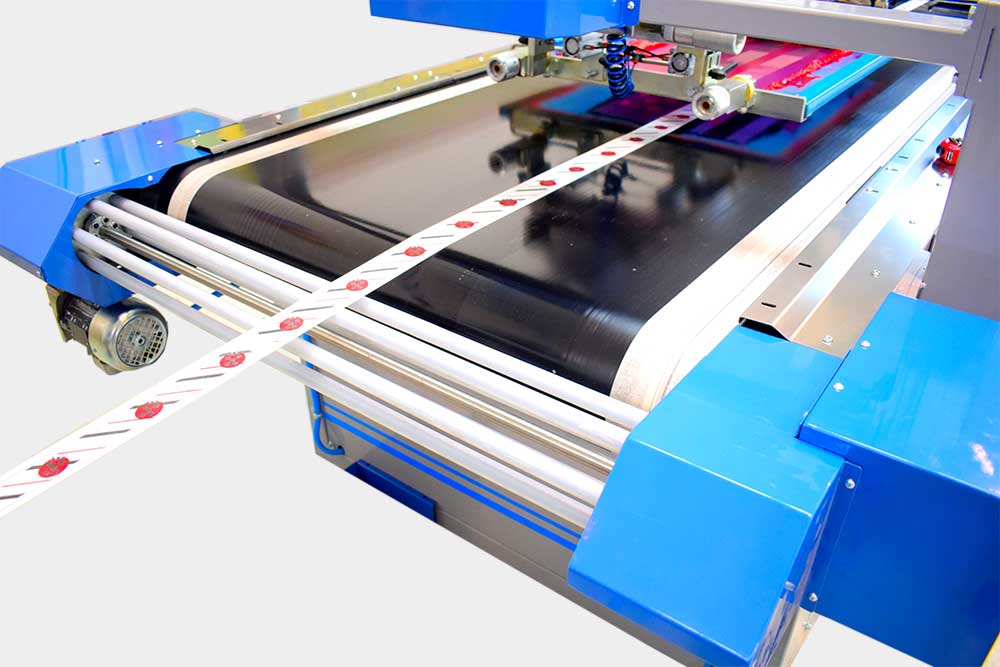

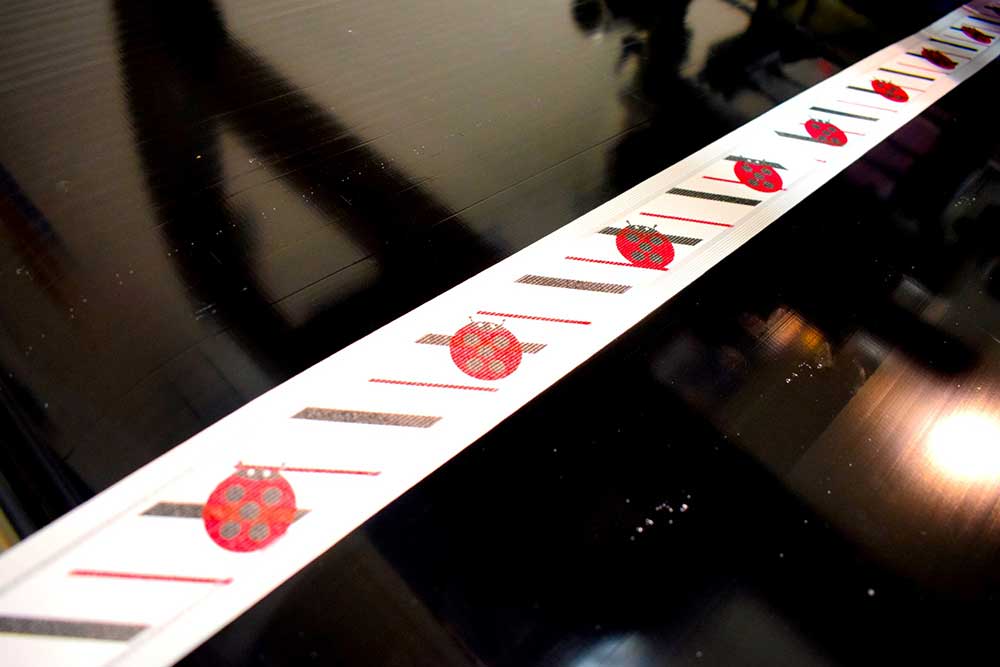

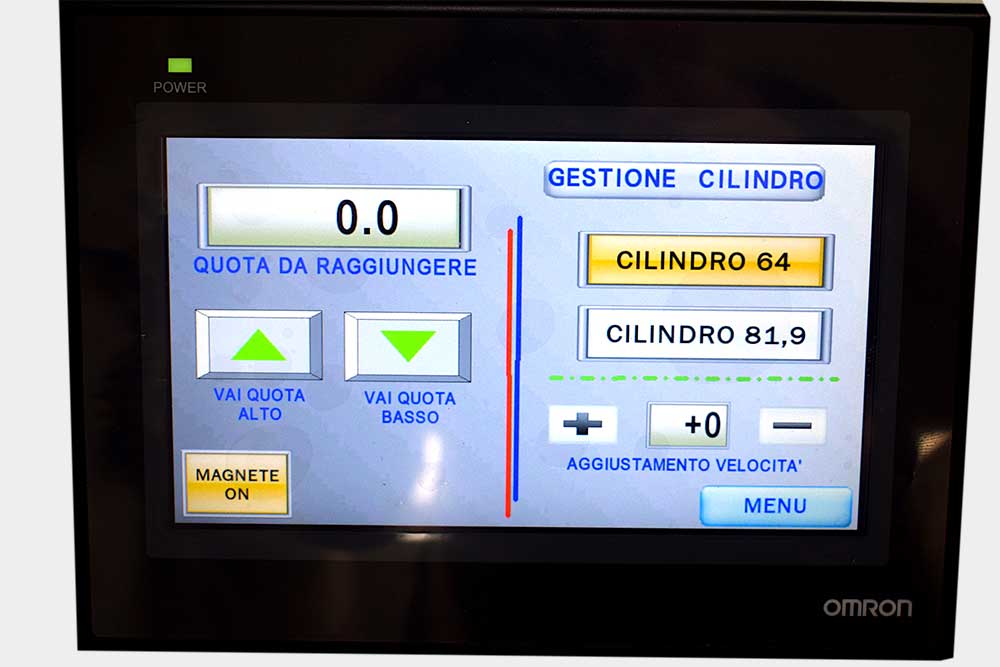

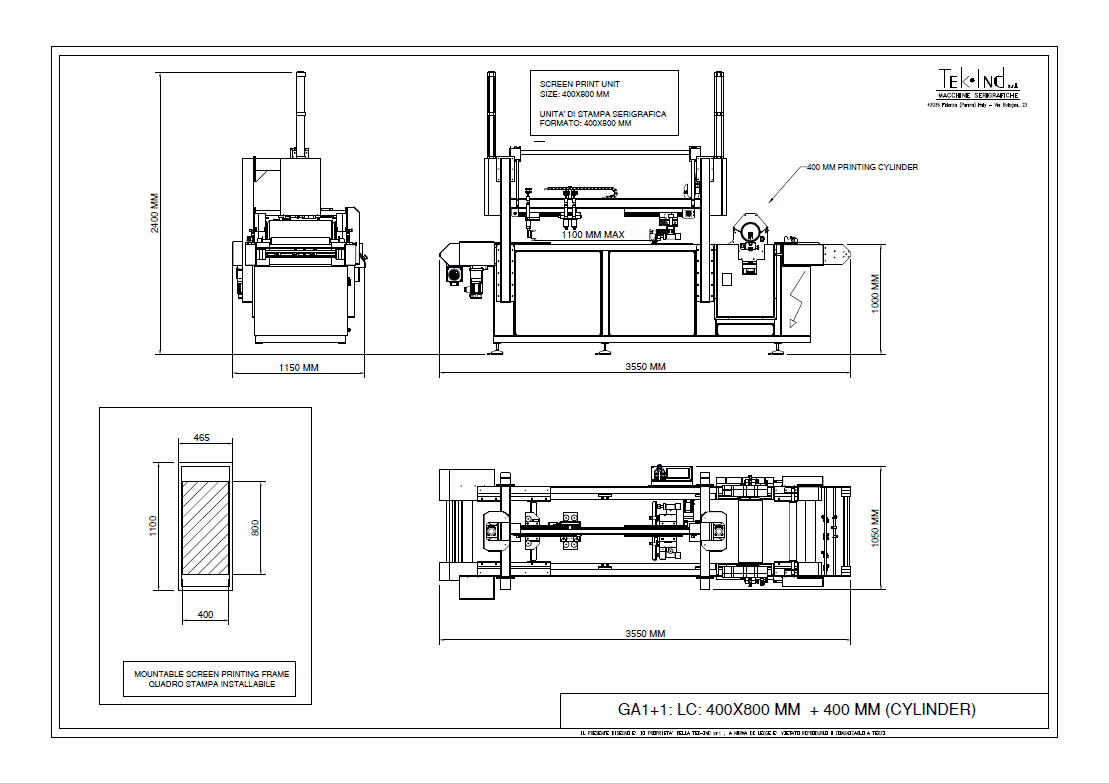

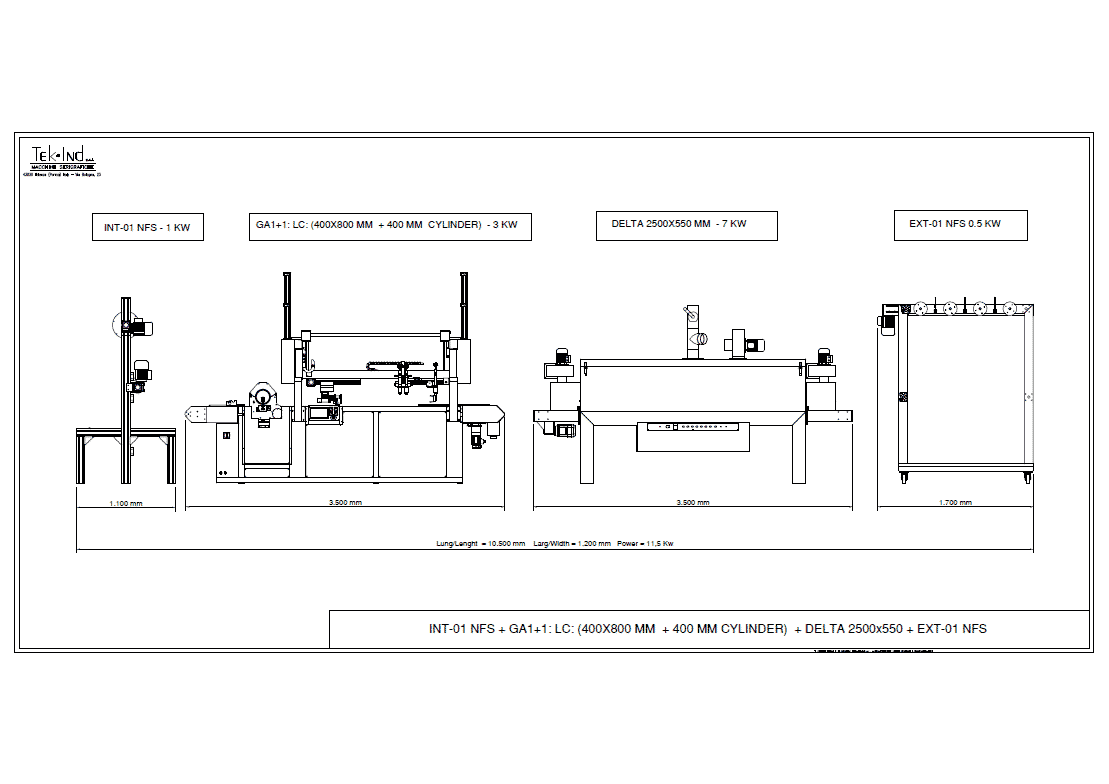

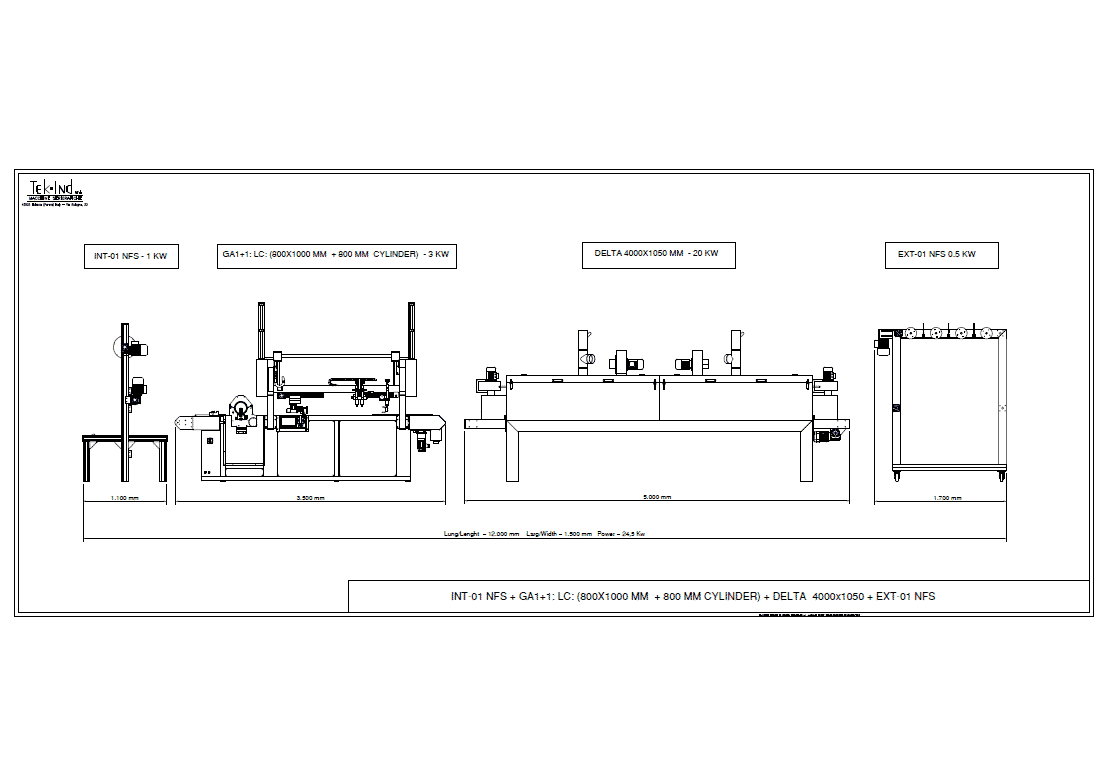

The printing machine can incorporate both technologies (rotary + screen-printing), in this case, the printing machine is called Gamma: GA: one silk-screen printing colour + one rotary colour. Both technologies cannot work at the same time, however this solution can be useful as with the same machine it is possible to produce both continuous single-color prints with the rotary cylinder, and separate single-color prints that can be realized through a screen-printing frame. The characteristics of the rotary cylinder are the same as those described in the general pages of the printing cylinder. While the characteristics of the silk-screen-printing machine are the same as those described in the LC in one colour printing. As for the other machines, an introduction is required INT-01, an oven for drying the ink Delta and one exit to boxes EXT-01.

MAIN TECHNICAL FEATURES

- Printing Typology Silk screen printing + rotary printing

- Printing technology 1-color flat printing + 1 rotary cylinder: with this machine is it possible to make single-color prints both continuous through cylinder and discontinuous through screen printing.

- Printable Narrow Fabric Rigid narrow fabric and Elastric narrow fabric

- Printing Width Width 400 mm / 800 mm / 1200 mm / 1600 mm

Lenght 400 mm / 500 mm/ 800 mm / 1000 mm / 1200 mm / 1400 mm /1600 mm

* other print formats available upon request - Production capacity Screen Printing 12 stroke/minute; 6 Mt/h, Rotary 15mt/min

- Installed power 4 Kw

- Air Consumption 6-8 bar; 3mt^3/h

- External sizes (cm) GA(F.to: 400x500 mm) + Rotoscreen 400 dim: 1000x3500x2000 - (WxLxH)

GA(F.to: 800x1000 mm)+ Rotoscreen 800 dim: 1400x4000x2000 - (WxLxH)

* most requested sizes, other machine size are available upon request - Usable inks Water base inks, plastisol inks, silicones

- Complementary Equipment Introduction(INT-01), dryer(Delta), guided exit(EXT-01), Silicon pump (SP-Series), Shaker.